Roller Mill

Save money by grinding your own grain for feed

Reduce your costs by processing all types of grain without intermediaries (wheat, barley, oats, corn). All Valmetal Roller Mills produce a crumbled, fluffy feed that is easier for your livestock to digest than pressure-flaked feed. Get precise particle size every time.

When choosing the Valmetal Roller mill, you receive the years of experience we have to offer in assisting you in producing the best possible feed for your lifestock. It is also a great piece of equipment for making beer in microbreweries.

Download the BrochureAvailable models

- Basic 2R12 Model

- 2R12 model with proportioners

- 4R12 Model with proportioners

- 4R12 Dual hoppers and reserves

- 4R12 with double hopper

Basic 2R12 Model

Legs and large capacity hopper with magnet and adjustable sliding gate are standard equipment on models without proportioner. A 5” (13 cm) diameter tilting discharge auger is available (optional).

2R12 model with proportioners

When only one size of grain has to be processed, producing your own feed is easy with a model 2R12 equipped with proportioners

4R12 Model with proportioners

No matter the size of the grain used, the 4R12 model, equipped with proportioners, allows you to produce complete grain ration right on the farm.

4R12 Dual hoppers and reserves

This roller mill, automated by an electrical panel is indispensable to supply computerized feeding systems. The two bins will supply any type of feeder or mixer When a bin is empty, the roller mill starts automatically to refill and stops whn the bin is full.

4R12 with double hopper

The 4R12 is the largest in its category. It features 4 rollers of 12” (30 cm) long x 8” (20 cm) diameter. Its large capacity will impress you. It gives you the option of alternating between small and large grains without having to readjust the rollers or to roll grains of different sizes at the same time.

Features

Proportioners in option

Both models can be equipped with advanced and reliable proportioners.

Different types of grooved rolls

Easy roller setting. A single lever sets both rolls in seconds so you get the desired texture (2 levers on 4R12 models). 1-3/4" (5 cm) diame...

Tilting discharge auger

A 5" (13 cm) Ø tilting discharge auger is available for our Roller Mill, Hammer Mill or Grain Bin.

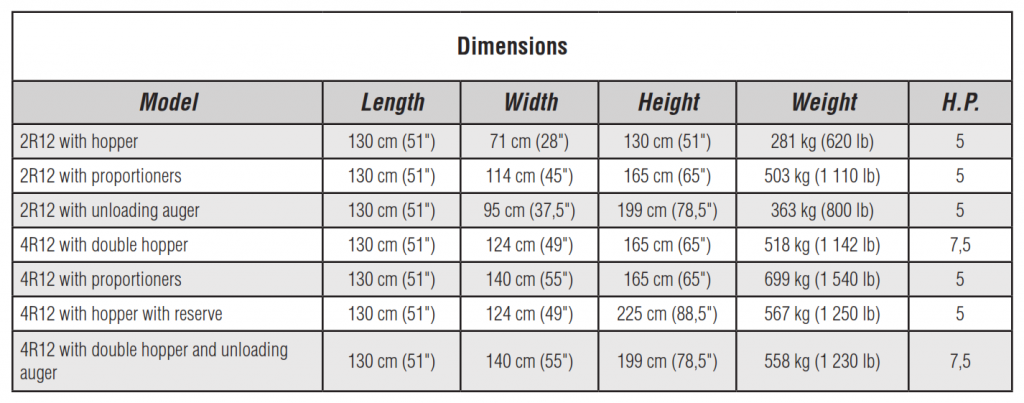

Specifications

- Easy roller setting. A single lever sets both rolls in seconds so you get the desired texture (2 levers on 4R12 models)

- 1 3/4″ (4,5 cm) diameter shafts withstand the severe pressure of rolling grain.

- Roller are made of high carbon steel, hardened ( 60 Rockwell C) for exceptional durability.

- A single 1/4 Hp AC motor drives all the proportioners. This is why our system always provides the most precise ration.

- Each measuring auger is controlled by a roller which features 25 retractable pins to properly measure each ingredient in the ration. To that, add the option of 4 different auger sizes and you have 100 possible adjustements per compartment.

- Measuring augers positive drive.

- The measuring rollers can be switched from “neutral” to “engaged” very quickly, saving tour valuable time. Each auger has its own access door to avoid the risk of spilling the other ingredients. It is also possible to add more proportioners at any time.