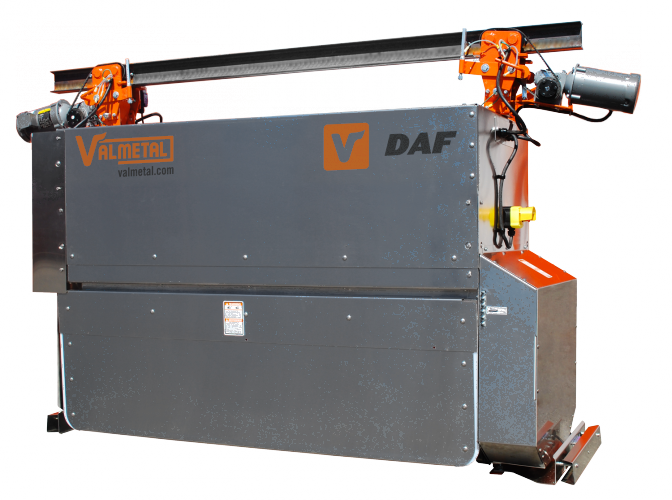

Rail Ration distributor – DAF

Very high flexibility and performance

The Valmetal TMR Distributor (DAF) can be adapted to almost any barn configuration and run on any type of existing track.

Download the Brochure

Painted steel

Stainless steel

Features

Versatile

Whether total mixed ration (TMR) or chopped hay, the DAF will eagerly distribute the feed, on either side. With an adjustable height box, th...

Simple

Sturdy fabrication, with few moving parts and a very efficient cycloidal transmission, the inside of the DAF is fully covered with ultra-abrasion resistant polymer.

Load cells

The components of the weighing system are incorporated into the control panel. Order management (including weight) is done through the touch screen control

Bumpers

Bumpers on both sides of the DAF are attached with 4 bolts for more durability.

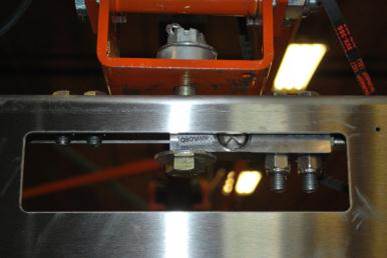

Restrictor

A flexible restrictor is now installed at the discharge door to avoid leaking when loading.

Color touch screen

A color touch screen feature more ergonomy

In Action !

Benefits

- Moving and unloading programmable speed (per group) per recipes

- Left or right programmable unloading option

- 0 to 70 feet/min (21 meter/min) speed

- New generation touchscreen for more accessibility

- 20 programmable actions for the entire system (ex: slow motion in curves , pause action, opening door action, ...)

- Ecological : Without any gas emissions, quiet, the Valmetal DAF is driven by regular AC motor

Other specifications

DAF is an alternative to the conveyor feeder. more and more dairy farmers acknowledge the effectiveness of the daf feeder :

- to supply the TMR managed by Valmetal’s Autoration

- to distribute silage directly from silos

- because, contrary to other alternatives (such as motorized carts), food never comes into contact with any wheel, which ensures its freshness and quality.

Optional weight system. Except the two loadcells, all components are integrated into the control panel

- Able to perform some inclinations(of the trail), the DAF is also available with a dual drive

- Grease bank

- Programmable oscillation for optimal loading

Also available with :

- Bumpers with programmable emergency stop at each end

- Détection d’obstacles par sonde ultrasonique

- Obstacle detection by ultrasonic probe

- Warning light or telephone reporting problem (in case of alarm)

- Detection of conveyor rotation of the DAF

- Photoelectric sensor load option (ex: greater accuracy when it is used with autoration, smart panel unloader …)

Figures

16

programmable start times

4

programmable load positions

25

sequences of 24 steps with full control of the order of actions

10

passes / group (max.)

5

programmable park positions

99

groups managed